Nipol® NBR

Nipol® nitrile (NBR) elastomers offer a good balance of performance and cost-effectiveness for applications needing fluid resistance, moderate heat resistance, and durability. We offer the broadest portfolio of NBR elastomers of anyone in the industry.

Nipol NBR is classified as a BG-BK polymer according to SAE J200 / ASTM D2000.

The best technical support comes from chemists with years of hands-on experience. Talk to our team about this product today.

The best technical support comes from chemists with years of hands-on experience. Talk to our team about this product today.

KEY ATTRIBUTES

Heat Resistance to 125°C

ZEON offers a full line of acrylonitrile butadiene polymers (NBR) for both general purpose and specialty applications. Nipol NBR elastomers offer the best balance of performance and cost for applications requiring the most severe oil, heat, and chemical resistance.

Broad Offering of Acrylonitrile Content

By varying the acrylonitrile (ACN) content, a good balance of low temperature performance and fuel resistance can be achieved. Nipol NBR is offered at ACN levels ranging from 19% to 50%.

Diverse Portfolio of Products

Nipol NBR elastomers are available in a variety of grades. Not only do the products cover a wide range of ACN levels, but they can be further categorized based on processability (Mooney viscosity) or by differences in polymerization chemistry. Nipol NBR elastomers can be segmented into hot polymers, NBR/PVC, pre-crosslinked grades, carboxylated grades, and more. Nipol NBR elastomers are also available in a variety of forms (powder, crumb, liquid, and bale).

| Type of Nipol NBR | Available Grades | |||

|---|---|---|---|---|

| Carboxylated Grades | Nipol NX775 | - | - | - |

| Ground Products | Nipol 1401LGF | Nipol 1472X | Nipol 1442 | - |

| Powder Products | Nipol 1411 | Nipol 1411C | Duomod DP5045 | - |

| NBR/PVC Polyblends | Nipol 1203WN | Nipol DN508SCR | Nipol DN171 | Sivic Grades |

Many more grades available… See the Grades Tables at the bottom of this page for all the possibilities!

APPLICATIONS

Abrasion Resistance

Carboxylated nitrile rubber (XNBR) is a terpolymer made from the polymerization of acrylonitrile and butadiene monomers with a third, carboxyl-containing monomer. Compared with conventional NBR, XNBR has higher tensile strength, modulus, and hardness, but the key performance advantage is the significant improvement in abrasion resistance. Nipol NX775 utilizes proprietary ZEON technology to offer enhanced scorch safety over other grades of XNBR, allowing for a wider processing window and making it a viable option in difficult to mold parts.

Suggested Grades

| Product Grade | % ACN | Mooney Viscosity | Specific Gravity | Hot/Cold | Comment |

|---|---|---|---|---|---|

| NX775 | 27 | 35-53 | 0.98 | C | Scorch Protected |

Stator Applications

Nipol 3640S was specifically developed for stator applications in the oil field industry. Nipol 3640S is a low viscosity polymer to aid in processing and also offers improved scorch safety over traditional NBR grades. Zeon later introduced Nipol 4040S, building on the excellent performance of Nipol 3640S but offering improved fluid resistance. Nipol stator grades maximize in-service parameters and are optimized on the relationship between dynamic properties and pumping efficiency. Testing has also shown superior hot water adhesion compared to other available grades.

| Product Grade | %ACN | Mooney Viscosity | Specific Gravity | Hot/Cold |

|---|---|---|---|---|

| 3640S | 36 | 30-40 | 0.98 | C |

| 4040S | 40 | 30-40 | 1.00 | C |

NBR/PVC Polyblends

NBR and polyvinylchloride (PVC) are highly compatible materials that offer a great balance of properties when blended together properly. This mixing process, called fluxing, is critical in obtaining the best properties possible. Sivic grades of NBR/PVC are fully-fluxed polyblends, which simplify production by eliminating PVC powder handling, simplifying logistics, and freeing up mixing capacity without additional investment. Sivic grades of NBR/PVC are ozone resistant, have excellent physical properties, and are easy to process, making them well suited for use in lay-flat hoses, cable jackets, and printing rollers.

Product Grade NBR/PVC Ratio ACN Viscosity Specific Gravity Comment

Sivic Z760 70/30 45 49-61* 1.07

Sivic Z740 70/30 41 45-57* 1.08

Sivic Z730 70/30 33 66-78 1.06

Sivic Z730M60 70/30 33 56-68 1.06

Sivic Z711 70/30 28 62-74 1.06

Sivic Z711LV 70/30 28 57-69 1.07

Sivic Z700PX 70/30 26 59-71 1.06

Sivic Z702 70/30 23 61-73 1.06

Sivic Z620 60/40 33 48-58* 1.09

Sivic Z530 50/50 33 55-65* 1.13

Sivic Z2710 60/40 33 19-29 1.09 Plasticizer extended, 70phr

*MS (1+4) @ 100°C

Friction Materials

Nipol 1411 and Nipol 1411C are very fine pre-crosslinked and branched 38% ACN NBR powders that differ only by partitioning agent type. The uniform particle size of these grades makes them more effective modifiers than other polymer-based options. While performance improvements are formulation dependent, typical benefits include improved pre-form green strength, increased brake effectiveness, fade resistance and compressibility, as well as other benefits like noise control, crack resistance and overall toughness.

Suggested Grades

| Product Grade | % ACN | Median Particle Size (mm) |

|---|---|---|

| 1411 | 38 | 0.1 |

| 1411C | 38 | 0.1 |

Composite Modification

DuoMod DP5045 and DuoMod DP5045F are pre-crosslinked, carboxyl-functional NBR powders that were developed as tougheners for epoxy resins used in high-performance composites. The unique surface morphology and ultra-fine particle size allows for excellent compatibility and optimum dispersion of the powder through the epoxy resin systems without the use of solvents. DuoMod powders will improve interlaminar tack more than other elastomeric or thermoplastic modifiers and users will note a significant increase in fracture toughness, even at low loadings.

| Product Grade | TG (°C) Typical Value | Median Particle Size (μm) | Comment |

|---|---|---|---|

| DuoMod 5045 | -5 | 50 | Crosslinked, carboxyl-functionalized |

Adhesives

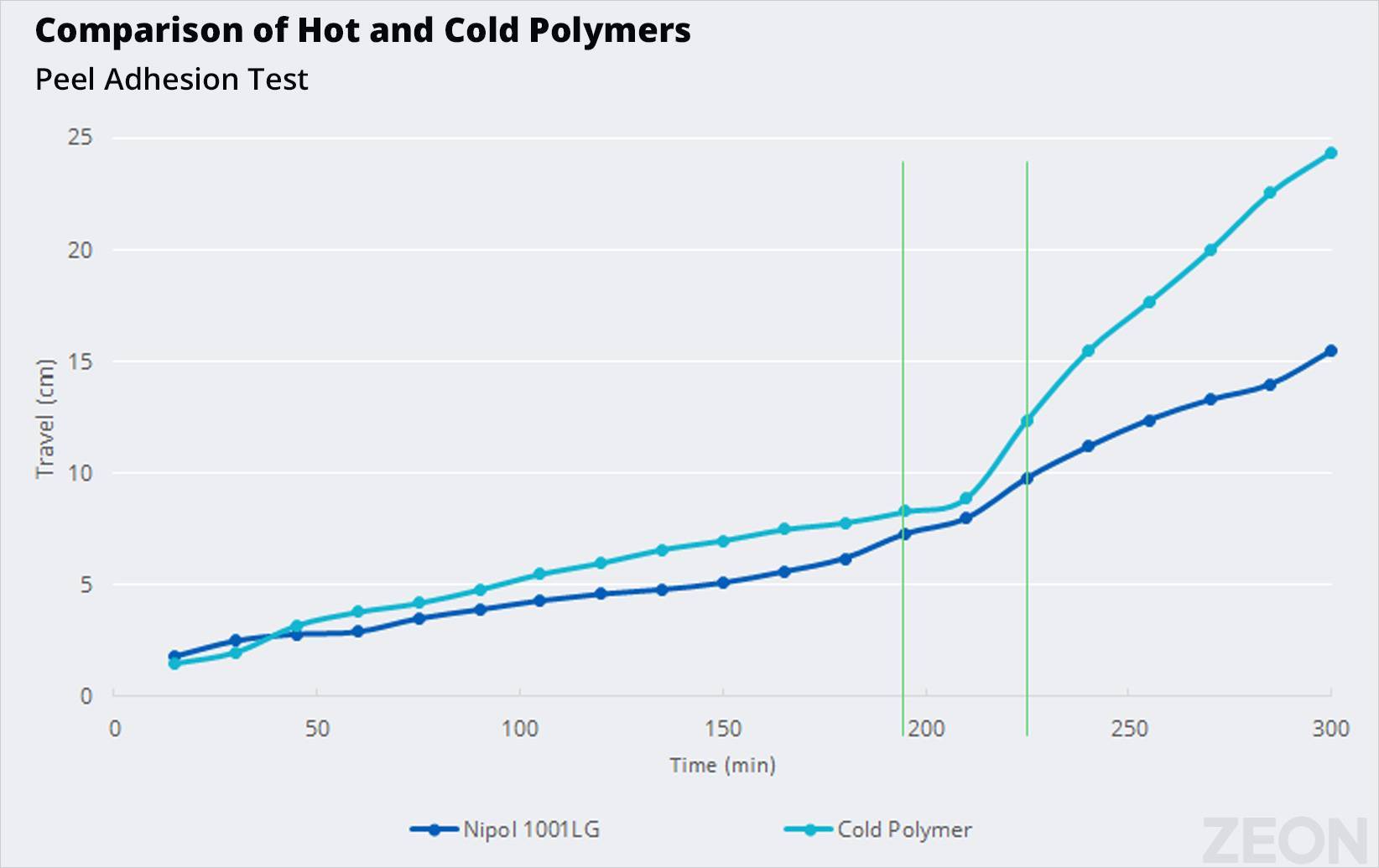

Hot polymers are traditionally used in adhesives because they have a highly branched microstructure. This results in increased entanglements between polymer chains, which in turn imparts better heat resistance and grip to the adhesive. Many of the baled adhesive grades are also available in a crumb form to ease the solvation process.

Nipol® NBR-Based Adhesives Technical Briefs:

Suggested Grades

| Product Grade | % ACN | Mooney Viscosity | Form | Hot/Cold | Median Particle Size (mm) | Cement Viscosity (cps) |

|---|---|---|---|---|---|---|

| 1001LG | 41 | 70-90 | Bale | H | · | · |

| 1401LGF | 41 | 70-90 | Ground | H | 9.5 | 1,000-10,000 |

| 1442 | 33 | 73-83 | Ground | C | 9.5 | 2,000-10,000 |

| 1472X | 27 | 20-35 | Ground | C | 9.5 | 100-1,500 |

Processing Aids

Nipol 1312 and Nipol 1312LV have such low molecular weights that they are actually highly viscous liquids. These grades are often combined with traditional nitrile polymers to reduce compound viscosity and improve the knitting and flow characteristics of the compound. Liquid NBR grades have better property retention than traditional polymeric plasticizers as well as superior extraction resistance due to the fact that they will crosslink into the polymer matrix on vulcanization.

Suggested Grades

| Product Grade | %ACN | Viscosity (cps) | Specific Gravity | Hot/Cold | AO Type |

|---|---|---|---|---|---|

| 1312 | 28 | 20,000 - 30,000 | 0.96 | H | NS |

| 1312LV | 26 | 9,000 - 16,000 | 0.96 | H | NS |

| 1312LVP | 26 | - | 1.12 | H | NS |

PVC Modification

ZEON makes many grades of acrylonitrile butadiene copolymers that can enhance the properties of flexible PVC compounds. These products are very easy to incorporate into PVC compounds due to the fact that they are available as a liquid or fine powder. Some of the benefits of introducing NBR as a modifier into a PVC compound include improved mechanical properties, impact resistance, chemical resistance, and low temperature flexibility.

Suggested Grades

| Product Grade | % ACN | Form | Viscosity (cps) | Specific Gravity | TG (°C) Typical Value | Median Particle Size (µm) |

|---|---|---|---|---|---|---|

| 1411 | 38 | Powder | - | 0.99 | -19 | 100 |

| 1422A | 33 | Powder | - | 0.98 | -26 | 100 |

| 1312 | 28 | Liquid | 20,000 - 30,000 | 0.96 | -39 | - |

Water Resistance

GRADES

Nipol® Nitrile Elastomers (NBR)

| Product Grade | % ACN | Mooney Viscosity | Tg (°C) |

|---|---|---|---|

| DN4555 | 45 | 48-63 | -8 |

| 1031 | 41 | 55-70 | -17 |

| 1041 | 41 | 75-90 | -17 |

| 1041L | 41 | 55-70 | -18 |

| 1051 | 41 | 63-78 | -17 |

| 1001LG | 41 | 70-90 | -17 |

| 4040S | 40 | 30-40 | -18 |

| DN4050 | 40 | 42-57 | -17 |

| 3640S | 36 | 30-40 | -24 |

| DN3650 | 36 | 45-55 | -24 |

| 1042 | 33 | 73-83 | -32 |

| 1052 | 33 | 45-60 | -34 |

| 1052J | 33 | 41-51 | -26 |

| 1052-30 | 33 | 25-40 | -36 |

| DN219 | 33 | 20-35 | -31 |

| DN3335 | 33 | 27-42 | -27 |

| DN3350 | 33 | 42-57 | -27 |

| DN3380 | 33 | 72-87 | -27 |

| DN202 | 31 | 58-68 | -34 |

| 1043 | 30 | 73-83 | -49 |

| 1053 | 29 | 45-60 | -26 |

| DN2850 | 28 | 42-57 | -32 |

| DN2880 | 28 | 70-85 | -35 |

| DN302 | 28 | 58-68 | -44 |

| DN302H | 28 | 73-83 | -41 |

| N917 | 23 | 55-70 | -50 |

| DN401L | 18 | 60-70 | -52 |

| DN401LL | 18 | 27-37 | -50 |

Nipol® Carboxylated Nitrile Elastomers (XNBR)

| Product Grade | % ACN | Mooney Viscosity | Tg (°C) |

|---|---|---|---|

| NX775 | 27 | 35-53 | -37 |

Nipol® Liquid Nitrile Elastomers

| Product Grade | % ACN | Form | Polymer Viscosity (cps) | Tg (°C) |

|---|---|---|---|---|

| 1312 | 28 | Liquid | 20,000 - 30,000 | -42 |

| 1312LV | 26 | Liquid | 9,000 - 16,000 | -42 |

| 1312LVP | 26 | DLC | - | -43 |

Nipol® Nitrile Powder Elastomers

| Product Grade | % ACN | Median Particle Size (mm) |

|---|---|---|

| 1411 | 38 | 0.1 |

| 1411C | 38 | 0.1 |

Nipol® Nitrile Crumb Elastomers

| Product Grade | % ACN | Mooney Viscosity | TG (°C) Typical Value | Type | Median Particle Size (mm) |

|---|---|---|---|---|---|

| 1401LGF | 41 | 70-90 | -18 | NBR | 6.5 |

| 1442 | 33 | 73-83 | -25 | XNBR | 9.5 |

| 1472X | 27 | 20-35 | -18 | XNBR | 9.5 |

Zealloy® Modifiers for Thermoplastics

| Grade | % ACN | Median Particle Size (µm) | Partitioning Agent |

|---|---|---|---|

| 1422A | 33 | 100 | Mineral |

Nipol® Polyblends and Oil-Extended Nitrile Elastomers

| Product Grade | % ACN | Mooney Viscosity | Specific Gravity | NBR/PVC Ratio |

|---|---|---|---|---|

| 1203WN | 33 | 55-70 | 1.07 | 70/30 |

| DN171 | 30 | 66-81 | 1.07 | 70/30 |

| DN508SCR | 38 | 40-50 | 1.08 | 70/30 |

Sivic® Polyblends

| Product Grade | % ACN | Mooney Viscosity | Specific Gravity | NBR/PVC Ratio |

|---|---|---|---|---|

| Z760 | 45 | 49-61 | 1.09 | 70/30 |

| Z740 | 41 | 45-57 | 1.08 | 70/30 |

| Z730 | 33 | 66-78 | 1.07 | 70/30 |

| Z730M60 | 33 | 56-68 | 1.07 | 70/30 |

| Z620 | 33 | 48-58 | 1.11 | 60/40 |

| Z530 | 33 | 55-65 | 1.14 | 50/50 |

| Z2710* | 33 | 19-29 | 1.09 | 60/40 |

| Z711 | 28 | 62-74 | 1.07 | 70/30 |

| Z711LV | 28 | 57-69 | 1.07 | 70/30 |

| Z700PX | 27 | 59-71 | 1.06 | 70/30 |

| Z702 | 23 | 61-73 | 1.05 | 70/30 |

| *Pre-plasticized with 70 phr phthalate free plasticizer | ||||

GET TECHNICAL ASSISTANCE