HyTemp® ACM

HyTemp® polyacrylate (ACM) elastomers have excellent long-term heat resistance (up to 200°C) and compressive stress relaxation, while providing superb resistance to petroleum and synthetic-based lubricants. HyTemp is broadly used in automotive seals (engine, transmission) and turbo diesel air management hoses.

HyTemp is classified as a DF to EH polymer according to SAE J200 / ASTM D2000.

The best technical support comes from chemists with years of hands-on experience. Talk to our team about this product today.

The best technical support comes from chemists with years of hands-on experience. Talk to our team about this product today.

KEY ATTRIBUTES

Heat Stability

HyTemp polyacrylate (ACM) elastomers offer significant improvements in long-term high-temperature resistance compared to other elastomer families. They can be compounded to withstand an impressive temperature range from -40° to 200°C. HyTemp is broadly utilized in automotive applications including valve cover gaskets, oil pan gaskets, rocker cover gaskets, and various seals.

Petroleum and Synthetic-Based Lubricants Resistance

HyTemp ACM provides superb resistance to petroleum and synthetic-based lubricants. This resistance makes HyTemp the best choice for engine gaskets and seals.

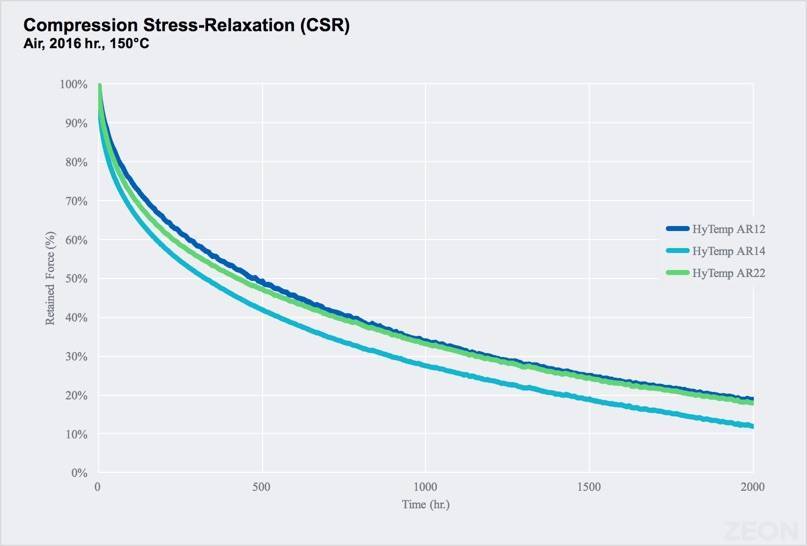

Excellent Sealing Force Retention

Representing some of the industry’s most advanced innovations, HyTemp ACM provides outstanding long-term compressive stress relaxation (CSR) and compression-set performance at elevated temperatures.

Cost and Performance Competitive

HyTemp ACM offers a lower-cost solution versus fluorinated elastomers, including FVMQ (fluorinated silicone) and FKM (fluorinated hydrocarbon) elastomers. HyTemp enables improved oil resistance versus AEM (acrylic/ethylene) and MQ/VMQ (silicone/vinyl functional silicone) elastomers.

| General Properties of ACM Compounds | Typical Range |

|---|---|

| Hardness, Shore A | 50 to 80 |

| Tensile strength, MPa | 7 to 14 |

| Elongation, % | 150 to 250 |

| Compression set, 70 hours @ 150°C | 5 to 60 |

| IRM901 Oil resistance, volume change, %∆ 70 hours @ 150°C | -5 to 5 |

| IRM903 Oil resistance, volume change, %∆ 70 hours @ 150°C | 10 to 60 |

| Specific Gravity | 1.3 |

| Elastomer Family | Relative Compound Cost Index | Maximum Service Temp, °C | Continuous Service Temp, °C | Minimum Service Temp, °C | Oil Resistance |

|---|---|---|---|---|---|

| HyTemp ACM | 1 | 200 | 175 | -40 | Excellent |

| MQ/VMQ | 2.5 | 310 | 275 | -100 | Fair |

| FKM | 14 | 290 | 260 | -30 | Excellent |

| FVMQ | 20 | 260 | 230 | -60 | Excellent |

| HNBR | 5 | 175 | 150 | -50 | Excellent |

| ECO/CO | 1.5 | 165 | 135 | -60 | Fair |

APPLICATIONS

Engine Sealing

Consistent performance in high-heat environments makes HyTemp ideal for automotive engine valve cover gaskets, oil pan gaskets, rocker cover gaskets, and other engine and transmission seals requiring superior sealing force retention in hot oil environments.

Consistent performance in high-heat environments makes HyTemp ideal for automotive engine valve cover gaskets, oil pan gaskets, rocker cover gaskets, and other engine and transmission seals requiring superior sealing force retention in hot oil environments.

Suggested Grades

| Product Grade | % Volume Swell | Gehman T100 (°C) | Mooney Viscosity |

|---|---|---|---|

| AR12 | 30 | -30 | 28-38 |

| AR12B | 30 | -30 | 28-38 |

| AR22 | 26 | -27 | 37-47 |

| AR14 | 30 | -40 | 28-38 |

| H570 | 40 | - 37 | 30-40 |

Automotive Engine Air Management

Air management systems for turbo-charged engines benefit from HyTemp ACM’s retention of properties at hot temperatures (175°C). HyTemp is commonly utilized for charge air cooler (CAC) hoses.

Air management systems for turbo-charged engines benefit from HyTemp ACM’s retention of properties at hot temperatures (175°C). HyTemp is commonly utilized for charge air cooler (CAC) hoses.

Hose manufacturers require broader processing characteristics combined with high throughput for economical production. This led to the development of the latest HyTemp ACM elastomers and specialized curative systems, which can be used for both molding and extrusion applications.

Suggested Grades

| Product Grade | % Volume Swell | Gehman T100 (°C) | Mooney Viscosity |

|---|---|---|---|

| AR212XP | 24 | -25 | 34-44 |

| AR214 | 30 | -40 | 28-38 |

Adhesives, Caulks, and Sealants

The tackiness of polyacrylate (ACM), coupled with extensive heat and oil resistance, makes HyTemp ideally suited for solvent-based adhesives, caulk, and sealant applications.

The tackiness of polyacrylate (ACM), coupled with extensive heat and oil resistance, makes HyTemp ideally suited for solvent-based adhesives, caulk, and sealant applications.

Suggested Grades

| Product Grade | % Volume Swell | Gehman T100 (°C) | Mooney Viscosity |

|---|---|---|---|

| 4051CG | 11 | -18 | 25-37 |

| 4451CG | 11 | -18 | 25-37 |

| 4454 | 63 | -41 | 22-34 |

GRADES

HyTemp® ACM Grades

| Product Grade | Gehman T100 (°C) | Mooney Viscosity* | Molding/Extrusion | Curesite |

|---|---|---|---|---|

| 4051EP | -18 | 35-47 | Both | Dual |

| 4051CGϮ | -18 | 25-37 | Both | Dual |

| 4065 | -30 | 27-45 | Both | Dual |

| 4052EP | -32 | 25-35 | Both | Dual |

| 4053EP | -42 | 23-31 | Both | Dual |

| 4054 | -41 | 22-34 | Both | Dual |

| AR71 | -18 | 42-54 | Both | Chlorine |

| AR71L | -18 | 29-41 | Both | Chlorine |

| AR715 | -24 | 27-39 | Both | Chlorine |

| AR72LF | -28 | 28-36 | Both | Chlorine |

| AR74 | -40 | 29-36 | Both | Chlorine |

| AR212XP | -25 | 34-44 | Extrusion | Carboxyl |

| AR22 | -27 | 37-47 | Molding | Carboxyl |

| AR12 | -30 | 28-38 | Molding | Carboxyl |

| AR12B | -30 | 30-40 | Molding | Carboxyl |

| H570 | -37 | 30-40 | Molding | Carboxyl |

| H570X | -37 | 34-44 | Both | Carboxyl |

| AR214 | -40 | 28-38 | Extrusion | Carboxyl |

| ϮCement Grade | *Mooney Viscosity ML (1+4) @ 100°C | |||

HyTemp® ACM Crumb Grades

| Grade | Gehman T100 °C | Mooney Viscosity | Partitioning Agent |

|---|---|---|---|

| 4451CG | -18 | 25-37 | Mineral |

| 4454 | -41 | 22-34 | Mineral |

HyTemp® Curative & Additive Grades

| Product Grade | Specific Gravity | Chemical Name |

|---|---|---|

| NS70* | 1.03 | Sodium Stearate Dispersion |

| NPC50* | 1.03 | Quaternary Ammonium Compound |

| SR50* | 1.03 | Proprietary Urea Compound |

| SC75 | 1.01 | Amine Cure Package |

| *No Post Cure System |

Zisnet® Grades

| Grade | Specific Gravity | Chemical Name |

|---|---|---|

| F-ET | 1.56 | Triazine Compound |

GET TECHNICAL ASSISTANCE